SUSTAINABILITY

In a bike-friendly world, our bikes can help drive the mobility revolution. If we are to succeed at making change for a more sustainable future, we must work together. We have a long journey ahead of us and are constantly making changes for the better. We continually.

adapt our products, location, and the way we work together to reduce our environmental impact through several measures

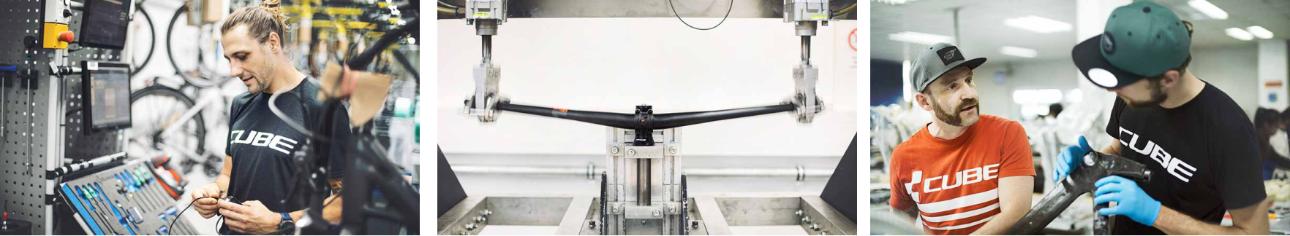

NO EXCUSES: THE BRAKES HAVE TO WORK

That’s why our engineers test various braking systems in our labs in order to guarantee perfect braking, stability and wear and tear resistance. Weather conditions are taken into account as well, which is why every brake is tested in dry and wet conditions. Once we're satisfied that a system works perfectly in both conditions, we move onto the second phase – checking durability. To test this, we automatically repeat 3000 braking cycles. Only brakes that pass this test - by showing minimal wear and tear - are used on our bikes.

Complete bikes are tested on our roller drum test rig. We

place the bike – fitted with production components – on the drum and add

weights to the handlebar, saddle and pedals (140kg in total) to simulate the

weight of a rider and all of his luggage. The drums rotate to simulate typical

road surface bumps so that the bike “rides” a given number of miles .and covers

certain obstacles. In total, each bike covers hundreds of miles and has to

overcome 1.5 million obstacles.

SPECIAL LAB TEST MOUNTAINBIKE

The head tube is a particularly vulnerable area on a moutain

bike, because large loads transmitted by the suspension fork are passed

directly through it. That's why we test intensively with this kind of load

separately, on a specific machine built just for this purpose. A realistic load

is put on a fork to simulate braking, jumping and obstacles – in total, the

head tube has to endure 50,000 of these cycles without damage before it can be

released for production.

SPECIAL LAB TEST ROAD BIKES

The head tube is a particularly vulnerable area on a moutain

bike, because large loads transmitted by the suspension fork are passed

directly through it. That's why we test intensively with this kind of load

separately, on a specific machine built just for this purpose. A realistic load

is put on a fork to simulate braking, jumping and obstacles – in total, the

head tube has to endure 50,000 of these cycles without damage before it can be

released for production.